PRAMUKH COTTON CYCLONE

Cotton Cyclone For Dust Collecting

Cyclones are the most common type of emissions control device used in agricultural processing operations.Cyclones are efficient, reliable, low‐cost, and require little maintenance. When used properly, cyclones effectively separate articulate matter from air streams, allowing compliance with state and federal air pollution regulations. Guidelines and techniques intended to help gin plant managers and operators determine if existing cyclones are correctly sized, properly constructed, and adequately maintained are reviewed. Methods presented are such that measurements can be made with minimal equipment and operating parameters determined with simple or no calculations.

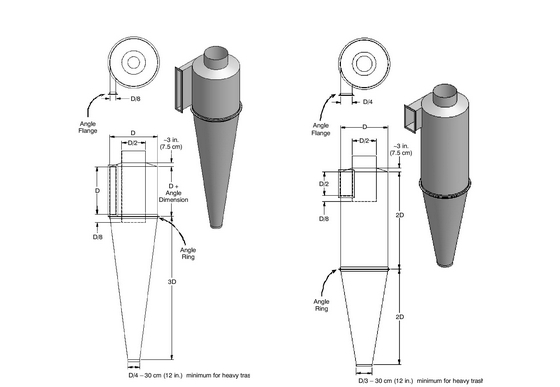

CYCLONE TYPES

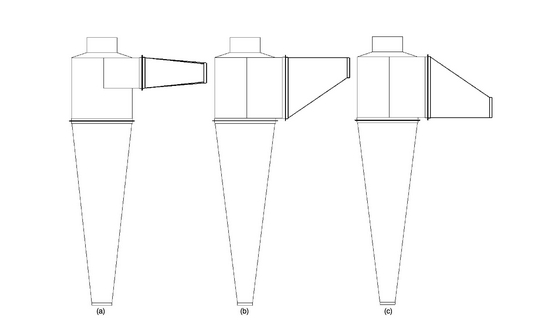

The two most common types of cyclones used in agricultural applications are the 2D2D (Shepherd and Lapple, 1939) and 1D3D (Witz, 1979) designs (figs. 2‐5). The first D in the designation indicates the length of the cyclone barrel relative to the cyclone barrel diameter and the second D indicates the length of the cyclone cone relative to the cyclone barrel diameter. Thus, the lengths of the barrel and the cone of 2D2D cyclones are equivalent to twice the cyclone barrel diameter. The 1D3D cyclones have a barrel length equal to the cyclone barrel diameter and a cone length equal to three times the cyclone barrel diameter. Note in

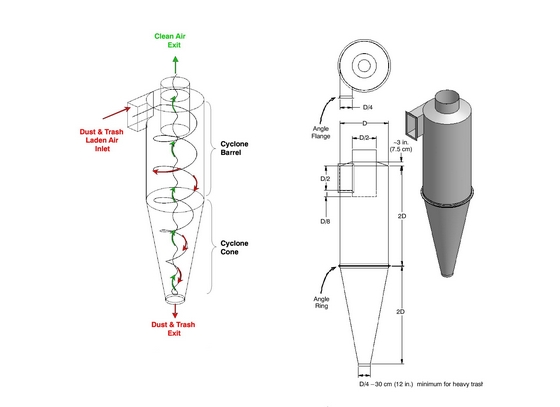

CYCLONE OPERATION

The main purpose of a cyclone is to collect the trash and dust which results from the cleaning, conveying, and drying processes at agricultural facilities. The trash and dust laden conveying air enters the top of the cyclone and then spirals downward (fig. 1). Centrifugal force moves the trash and dust to the outside wall where they slide downward to the bottom of the cyclone to drop out of the trash exit. At the bottom of the cyclone the air reverses direction and moves upward in a smaller spiral to exit out the clean air exit at the top of the cyclone.

- Provide Engineers For Ginnery & Oil Mill

- Reparing Facility For All Types Gin Machines

- Supply Double Roller & Saw Gin Parts

- Export Facility

- Provide Electrical Solutions

- Bulid Strong Steel Structure

- One Way Solutions For Ginning & Oil Mill

Service Lists

Testimonials

Year, 2014 Isika hametraka Pramukh Double Roll Machine & Automatic System,Izany no tsara indrindra System Install amin’ny landihazo ginnery.

Mr,Salim Dhramsi- Owner Cotton Ginnery9 juillet 2014 Je vous écris cette lettre pour vous remercier pour votre travail remarquable sur le projet Coton usine d’égrenage. Votre expertise rouleaux de la machine et l’attention au détail étaient extrêmement utiles sur le projet.

Kamal Butt - C.E.O : Cotton Ginnery, Oil Mill