PRAMUKH : HEX BOLTS

We Are Manufacturer & Exporter High Quality hex Bolts With the support of our dexterous team of professionals, we provide clients a high quality range of alltypes bolts this bolts is manufactured from supreme grade components at our well-equipped production unit in conformity to the international standards of quality. Owing to optimum functionality, resistivity to adverse conditions, longer service life and high performance, our offered array has gained huge demands across the global market. Moreover, we are offering this expeller parts to clients at highly affordable prices.

Our all expeller are developed by our experienced engineers, which have the complete know-how of steel quality, structure, hardness, parallelity and toothing shape. The perfect composition of this guarantees an exclusive product with extraordinary long lifetime and optimal industrial bolts results. Pramukh Steel Industries are offered for all types nut-bolts and hardware items. we supply our Bolts and other hardware items in india as well as africn countries.

BOLTS : HEX HEAD BOLTS

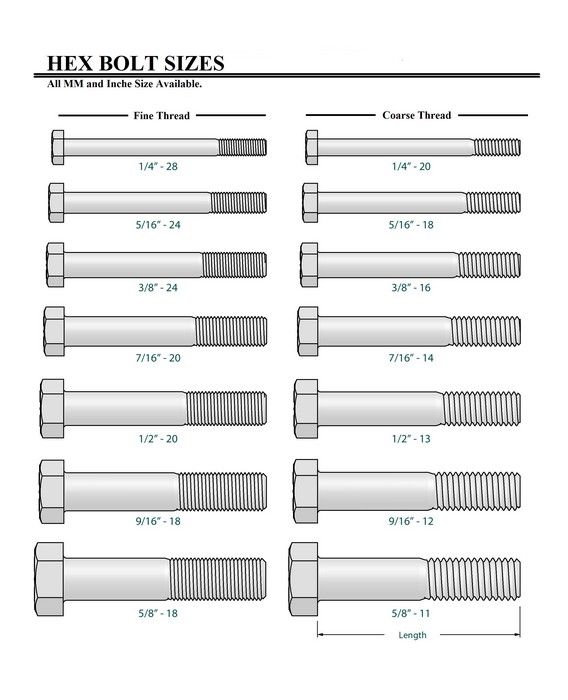

Tow Types of Hex Bolts

Coarse Threads

Coarse threads are more durable and have greater resistance to stripping and cross-threading. The height of each thread is greater than the corresponding fine thread so there is more material between each thread making flank engagement greater.

Coarse threads are commonly used where rapid assembly or disassembly is required.

Coarse threaded fasteners install much faster than fine threaded fasteners. A ½-13 bolt assembles in 65% of the time it would take to assemble a ½-20 bolt. The ½-20 bolt advances one inch in 20 revolutions, while the ½-13 bolt advances one inch in only 13 revolutions.

Coarse threads are not affected by plating build-up as much as fine threads. The same amount of plating on a coarse thread would use up a greater amount of the plating allowance on a fine thread. Fine threads experience more gaging and assembly problems due to plating build-up than coarse threads, as there is less material between each thread flank.

When using Coil Thread Locking Inserts, or other stainless steel threaded fasteners, coarse threads are much less likely to experience galling than fine threads. Fine threads have more rotations as we discussed previously and this coupled with the closer pitch diameter fits of fine threads increases the tendency for fine threads to experience thread galling.

Fine Threads

Fine threaded bolts are stronger than the corresponding course threaded bolts of the same hardness. This is in both tension and shear due to the fine threaded bolts having a slightly larger tensile stress area and minor diameter

Fine threads have less tendency to loosen under vibration due to their having a smaller helix angle than coarse threads. Fine thread Locking Insert grip coils are more flexible than coarse thread insert corresponding size grip coils, and are less likely to take a set under vibration conditions.

Fine threads because of their finer pitch allow for finer adjustments in those applications that need this characteristic.

• Fine threads are commonly used for nuts and bolts in high strength applications. • While applications vary, in general, fine threads are approximately 10% stronger than coarse threads. • They have less of a tendency to loosen under vibration because the smaller lead or thread helix angle provides better wedging action when the assembly is tightened. • Fine threads are also used for fine adjustment and thin walled applications due to the shallower thread height. • Fine threads are generally easier to tap. Since the thread height is shallower, the chip load per tooth and chip volume are lower, resulting in less tapping torque and breakage, particularly in difficult to machine materials. • Less chip volume also means that more lubrication will reach the cutting teeth resulting in longer tap life. • Fine threads require larger tap drill than for coarse threads, which improves the performance of the drill and tap

| TECHNICAL DATA | STAINLESS STEEL | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FINE THREAD | |||||||||||

| STANDARD THREAD | |||||||||||

| TECHNICAL DATA | STAINLESS STEEL3/1/6 | ||||||||||

| FINE THREAD | |||||||||||

| STANDARD THREAD |

.......................................................................................................

| TECHNICAL DATA | ZINC PLATED STEEL | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FINE THREAD | |||||||||||

| STANDARD THREAD |

.......................................................................................................

| TECHNICAL DATA | Grade 8 steel plain finish | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| STANDARD THREAD |

.......................................................................................................

| TECHNICAL DATA | Chrome Bolts | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| FINE THREAD | |||||||||||

| STANDARD THREAD |

Service Lists

- Provide Engineers For Ginnery & Oil Mill

- Reparing Facility For All Types Gin Machines

- Supply Double Roller & Saw Gin Parts

- Export Facility

- Provide Electrical Solutions

- Bulid Strong Steel Structure

- One Way Solutions For Ginning & Oil Mill & Hardware items

Testimonials

Year, 2014 Isika hametraka Pramukh Double Roll Machine & Automatic System,Izany no tsara indrindra System Install amin’ny landihazo ginnery.

Mr,Salim Dhramsi- Owner Cotton Ginnery9 juillet 2014 Je vous écris cette lettre pour vous remercier pour votre travail remarquable sur le projet Coton usine d’égrenage. Votre expertise rouleaux de la machine et l’attention au détail étaient extrêmement utiles sur le projet.

Kamal Butt - C.E.O : Cotton Ginnery, Oil Mill